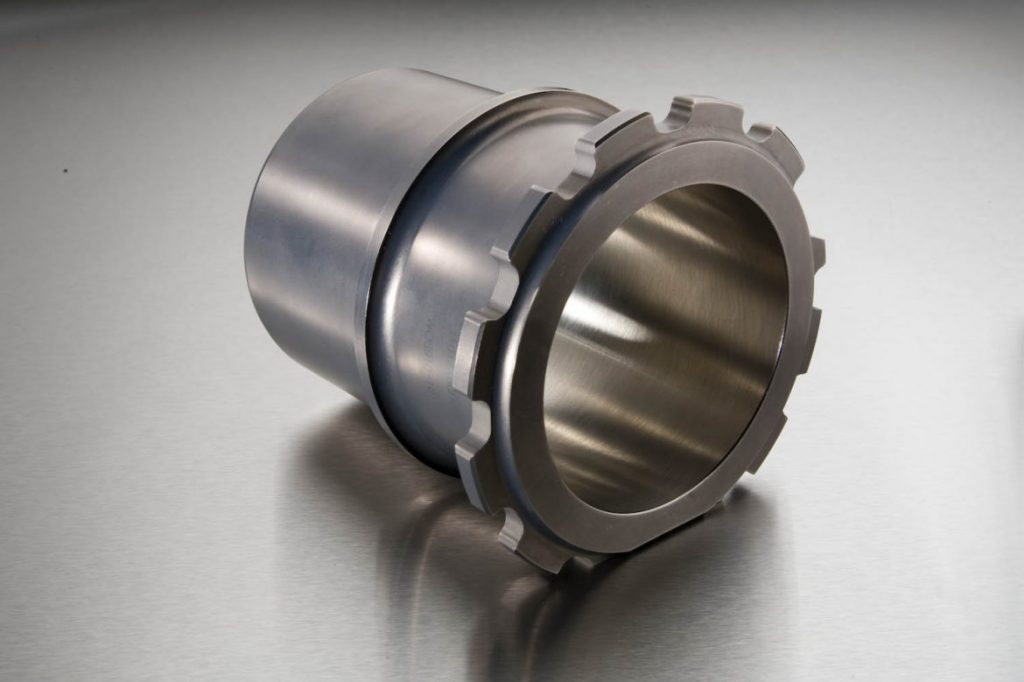

capricorn Automotive nickel-ceramic coated cylinder liners are at the forefront of high-performance engine technology, offering unmatched durability and efficiency for demanding applications. We specialise in the design and maunfacture of these advanced cylinder liners utilising a range of materials including aluminium, high strength steels and MMC.

Our in-house proprietary nickel-ceramic coating process enhances the performance and longevity of cylinder liners by providing superior resistance to friction, wear, and thermal stress. This makes them ideal for high-performance engines used in motorsport, niche automotive, and aerospace applications, where engine reliability and longevity are critical. The coating also improves heat dissipation, reduces friction, and enhances the overall efficiency of the engine, resulting in better performance under extreme conditions.

Whether used in Formula 1 engines, aerospace propulsion systems, or other high-performance applications, our nickel-ceramic coated cylinder liners are engineered to withstand the most demanding environments. At Capricorn Automotive, we ensure that every liner we produce meets the highest standards of precision, quality, and durability, helping our clients push the limits of engine performance.

Advancement in coating technologies also allows us to offer zinc phosphate, nickel PTFE, and xylan coatings to the outside dimensions of the cylinder liners to prevent micro-welding, corrosion, and galling.

Our longstanding partnership with Loughborough University helps us to reinforce this vision keeping us very much at the cutting edge of engine technology.

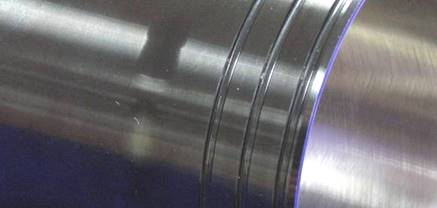

Standard surface bore finish:

• 0.15<Ra<0.3

• 0.1<Rpk<0.3

• 0.6<Rk<1.2

• 0.3<Rvk<0.6

• OD to a surface finish of 0.8 Ra.

• ID round to within 0.010mm

• ID parallel to within 0.010mm

• Bore size tolerance + 0.010mm / – 0

• Honing cross hatch angle 35° inclusive.