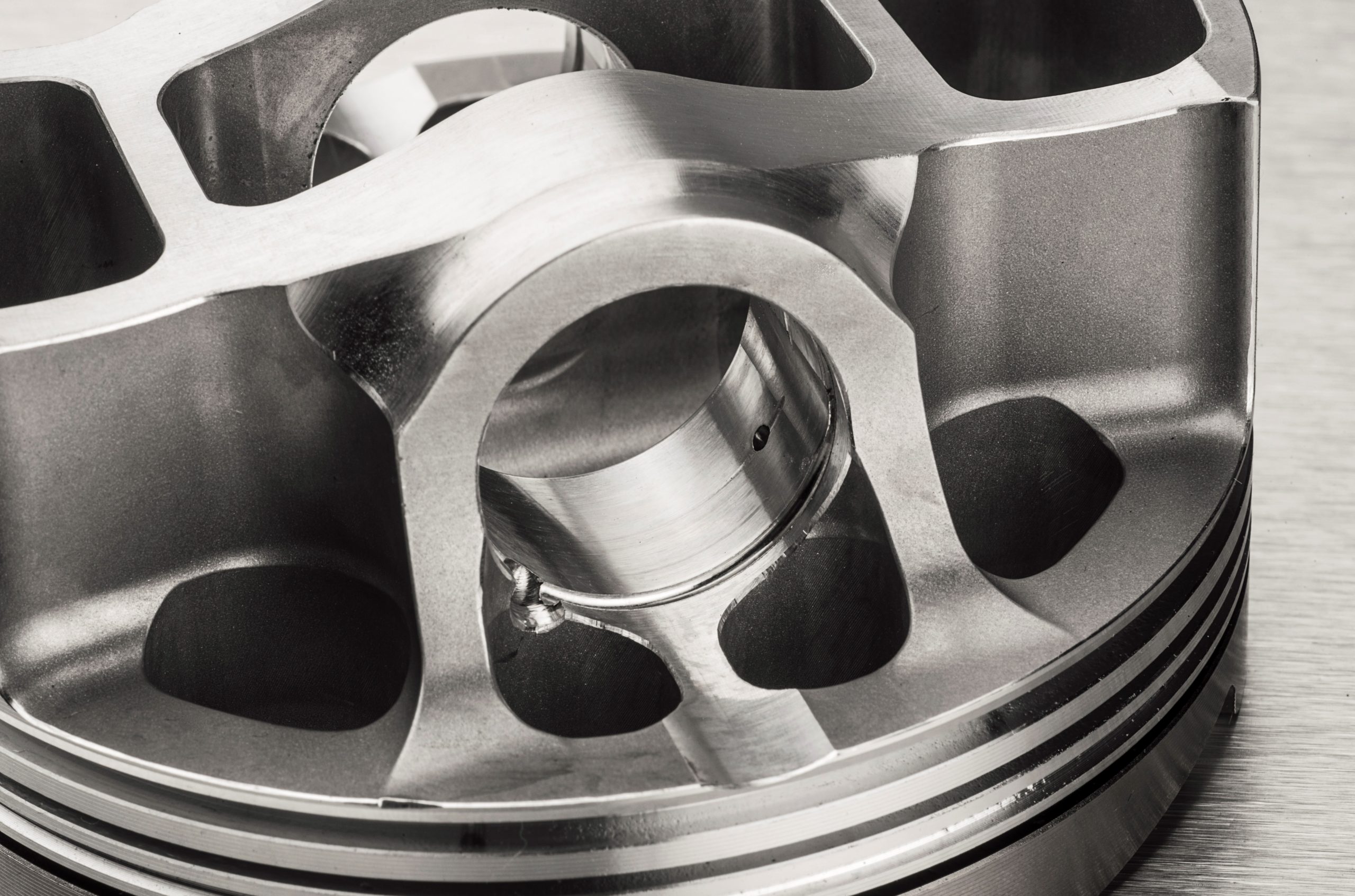

For over 20 years capricorn Automotive Ltd has been at the leading edge of forged and billet machined piston design and manufacture. Utilising the very latest in material developments, advancements in design, and the latest in machining technology we help our customers, the leaders in motorsport, and automotive to stay ahead of their competition.

Capabilities

Utilising the latest CAD analysis software allows us to carry out finite element analysis as well as thermal expansion analysis using COSMOS, SolidWorks, and ProEngineer software. Working hand in hand with our customers ensures that their design requirements are met first time all the way through to the final product where our state-of-the-art Quality Control Department certifies that the parts are to drawing before being expertly packed and shipped to the customer.

Our in-house ISO-thermal precision closed die forge press along with our full heat-treatment capability gives us full control of the whole manufacturing process. Optimised near-net forging design, production-intent routings, and bespoke gauging allow us to offer customers small to medium production volumes of up to 50,000.

For customers like our OEM Prototype Departments who are working to tight timescales or have prototype or development requirements, billet machining allows us the flexibility to meet constantly changing design requirements and is the preferred route before investing in forge tooling.

Our expertise covers pistons for all road and race engine applications, notably high- pressure turbos. Further experience in machine-in gallery cooled pistons, forged-in top ring reinforcement pistons offer solutions for heavy-duty applications.

But we never stand still - we constantly strive to push the boundaries in all key areas of design and manufacture with the end goal to always offer the best possible solution to the customer. Our wide range of experience especially in regards to structural, thermal, and tribodynamic characteristics allows us to realise this philosophy. It’s the only way to improve our solutions and to stay ahead of the competition.

Innovation needs impulse. That’s why capricorn AUTOMOTIVE Ltd cultivates a long-term and trustful partnership with Loughborough University. This relationship has already provided fundamental insights into the last remaining sector for significant performance enhancement – the origin of friction loss inside cylinders.